Чехия – 2010 – Металорежущее и кузнечно-прессовое оборудование

Чехія – 2010 – Металорізальне і ковальсько-пресове обладнання (анг.)

Metal-Cutting and Metal-Forming Machines or “Where Manufacturing Begins”…

Petr Zemánek, Director, Association of Engineering Technology, Prague

The field of metal-cutting and metal-forming machines is undoubtedly one of the main propellers in the process of achieving and maintaining competitiveness in any economy. For this reason, the state of the field can be considered an indicator of sorts that shows the level of economic health and the efficacy of management, both from the microeconomic and macroeconomic points of view. The Association of Engineering Technology, being an interest-group of forty-six of the most important Czech and Slovakian producers of metal-cutting and metal-forming machines, not only carefully monitors development in this field, but also protects the interests of its members within the individual programme topics of its activities and provides them with support and services.

Position of the Field in Current Economic Conditions

Current results in the field, just like development trends that have always been the subject of analyses, need to be evaluated in relation to pan-European and global development of the economy. Because of its high level of openness and its participation in wider, transnational supplier-consumer chains, the Czech economy has been significantly hit by the economic downturn that immediately followed the onset of the financial crisis. Let us not forget that over 80% of the production of Czech metal-cutting and metal-forming machines is intended for export and that this export is, to a great degree, intended for countries outside of the European Union. It is this fact that represents a certain advantage for the metal-cutting and metal-forming industry, because non-European markets, whose absorption capability is now rising significantly, were being abandoned by a number of other fields in the last twenty years. On the other hand, the substantial volatility and long-term strengthening of the Czech Crown have to be considered a disadvantage for fields oriented at export, because both these trends make export significantly more expensive and negatively influence the competitiveness of Czech exporters. This is also the reason why Czech exporters are calling for an expeditious accession to the Euro, but the Government has not had much understanding for this demand so far.

Generally, it can be said that the conditions which domestic producers of metal-cutting and metal-forming machines had to live with during the recession were far from ideal. Following several extraordinary years of economic growth, which came close to 6%, the collapse of world trade along with domestic consumption contributed to the fact that the real GDP decreased by over 4% in 2009. And it was industry that accounted for over one half of the overall decline.

BRICS, Germany, or We - Who Will Head the Post-Crisis Start?

If we allow that the worse consequences of the crisis are already behind us, and the longingly awaited revival of the market is becoming a reality, especially in BRICS countries (Brazil, Russia, India China, South Africa) and subsequently in Germany as well, the truth still holds that the cycle of recovery and the expansion of production bases has not yet been started to a sufficient degree in other countries of the Eurozone. The aforementioned revival thus still remains somewhat fragile, and some reputable world economists even suggest the possibility of a new recession.

However, for the time being, it looks as if the field of metal-cutting and metal-forming machines has received a positive impulse after all – in the form of an increase in the number of orders. Telling symptoms recorded by the first batch of this year’s statistics of production and export really seem to support this. As it is, a number of European and non-European companies in the machine-building and other fields have started to invest in purchases of new equipment for their production lines during the post-crisis period, and our producers should therefore be adequately prepared for this situation. A technically and price-wise competitive production of top machines, components and complexly equipped workplaces, fitted with modern technologies, will become the show-piece of the metal-cutting and metal-forming field – provided our producers succeed in capturing this fast development trend in time. Because foreign competition is, it would seem, more than well prepared and intends to demonstrate its strength this autumn at the largest trade fair in the field, the EMO Hannover 2011.

"Asian Tigers" - Danger, or Stimuls?

Asian markets may serve as a textbook example of rapid development. Their dynamics have historically moved from Japan through Korea into China. This country, with an unimaginable land area, has a huge, as yet unsaturated internal market that can absorb both local and imported production in sufficient quantities. However, should the demand in China decrease significantly – and concerns regarding the overheating of the economy and the burst of the investment bubble have been cropping up ever more often – it is necessary for European producers to be ready for an aggressive influx of Asian competition in the rest of the world. Economic development in the whole of Asia thus needs to be monitored very closely, and changing conditions of both an economic and political nature have to be acted upon very quickly.

Road towards Improved Prestige in Technical Fields Does Not Have to Be Hard

Following more than two years of recession, many European countries, and the Czech Republic as well, see the necessity for a quick transition from “crisis” and considerable stimulating economic measures towards a policy of implementing medium-term consolidation strategies, which include intensive work with human resources. This process starts, without a doubt, on the level of secondary or vocational education, which needs to be attended to across all fields and with a special emphasis on the education of quality technical intelligence.

As has already been mentioned, this is by far not an exclusively Czech problem. It has been suggested for some time now that it is in the European interest to build sufficient capacities and functional mechanisms in order to be able to predict the needs of the labour market on both the national and EU levels. Specifically, this means improving the accuracy of research methods, regular updating of databases and thorough monitoring of demand and supply. At the same time, we have to realise that there isn’t an exact method that allows us to make reliable predictions regarding the future needs of individual fields in relation to the educational system, social programmes and programmes for the development of human resources; mainly because the majority of these programmes is – unlike the relatively volatile and hard-to-predict fluctuations in the global economy – of a downright medium-term to long-term nature.

When working with youth, we have to continue with some proven models and functional methods, but mainly we have to seek new paths. In recent years, interest has been concentrated chiefly on intensifying the collaboration between producers and regional schools and vocational training institutions. Apart from that, attention has been paid to quality marketing of promotional events that serve to awaken the interest of students in technical fields. For example, competitions for young programmers of CNC machines from secondary schools have proved very successful. These competitions have been held for the past three years as part of the accompanying programme of the International Engineering Fair in Brno. Groups of students compete by trying to build a programme for machining a workpiece shown in a drawing. A correctly built programme of the best technological quality is then tried on a real machine. The winners’ reward is not only a diploma and an award, but also promotion for their school and their names. It is very gratifying that we have been able to secure the support of the Ministry of Industry and Trade for this event for two years running.

Science and Research in Close Contact with Production Practice

Further development in the field of metal-cutting and metal-forming machines is also related to the necessary acceleration of the process of implementing new technologies and taking into account the requirements for decreasing energy consumption of machines and the negative influences on the environment during their entire life-cycle. There are a number of projects, on both the national and European levels, that focus on these issues. These projects are being investigated by young technicians from the Research Centre of Manufacturing Technology at the Faculty of Mechanical Engineering of the Czech Technical University in Prague. A result that bears mentioning is the preparatory study for the implementing regulation of the Directive of the European Parliament, establishing a framework for the setting of eco-design requirements for energy-related products. In this regard, the European Association for Collaboration on Production of Machine Tools, CECIMO, as well as experts from the Association of Engineering Technology, have been very active. The rate of success of the output from these expert assignments will be measured by the oft-emphasised higher rate of competitiveness of the final products of our producers on the world market.

State Support Is Not Only Welcome But Essential

The speed, thoroughness and efficacy of these processes will also depend on the Government’s efforts to form a positive business environment. The most frequently discussed measures include the elimination of obstacles to entering the market, stronger pro-export policies and strengthening fair economic competition. The realisation of these reform steps will be somewhat hampered by some of the debts the Czech Republic has on the macroeconomic level. The main issue will be the reserved approach towards the activities of the European Union oriented at improving the competitiveness of the industry. The overly severe budget cuts that look likely to send the gross domestic product down below 2% again, i.e. beneath the average in the Eurozone, will surely play their part as well.

Even Statistics Can Delight

Despite the listed problems related to the consequences of the crisis and the general economic situation in the country, the field of metal-cutting and metal-forming machines still remains one of the flagships of Czech industry. Official statistics published by CECIMO, seated in Brussels, put Czech producers in a very flattering position when compared to world and European classifications: 13th place in the world and 7th place in Europe in the amount of production of metal-cutting and metal-forming machines. Considering the size of the Czech economy and the fact that the majority of production companies is in Czech hands and they manufacture final products, this is an undeniable success. For several years now, the renowned Italian magazine, Tecnologie Meccaniche, which is entirely dedicated to the field of metal-cutting and metal-forming machines, tools, automation and robotisation of technology processes, has been publishing a so-called European classification of the first 100 largest producers in the field. Besides the traditional field leaders from Germany, Switzerland and Italy, five to eight Czech companies have regularly made the list in the last three years.

”Know Thyself” (Nosci se ipsum)

Self-reflection has traditionally been one of the necessary conditions for a successful foray into any kind of human endeavour. Current entrepreneurial practice shows us that this ancient wisdom has not lost any of its truth. In conclusion, let us contemplate the weaknesses and the qualities of Czech business entities in the machine-building field that have been identified by confrontation with foreign firms. We have to admit that there are still many deficiencies in the continuous mapping of new markets, a flexible search for often unrepeatable business opportunities and a quick response to results of marketing surveys. The effort to remedy these deficiencies should be accompanied by an effort to improve the presentation of our own qualities and acquire a broader knowledge of the technological and production capacities of our companies, which really can bear comparison to foreign competition. We just have to make it known. In short, we cannot live on the former glory of traditional machine-building brands; instead, we have to make the new ones world-renowned as well and as quickly as possible.

Czech businesses have a number of qualifications for the fulfilment of these premises. Our position in Europe and the world is favourable – the Czech Republic is not considered a superpower, at least not in the negative meaning of the word. Czech producers are capable, especially when under pressure, of collaborating on realising efficient collective solutions and putting behind their feelings of exclusivity for a time. The Czech entrepreneur has not lost his or her creativity, the ability to feel empathy and the skill to establish professional contacts with a high level of openness and friendliness. The future of the Czech machine-building industry will demonstrate up to what level we are able to utilise these distinctive qualities.

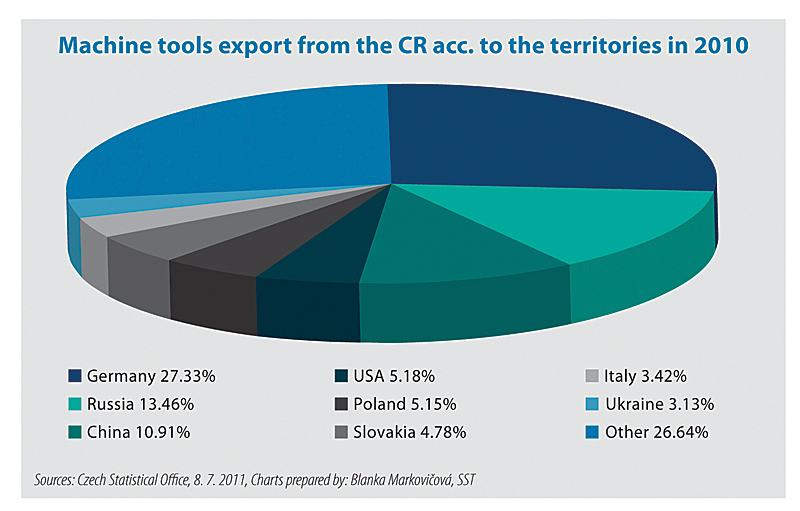

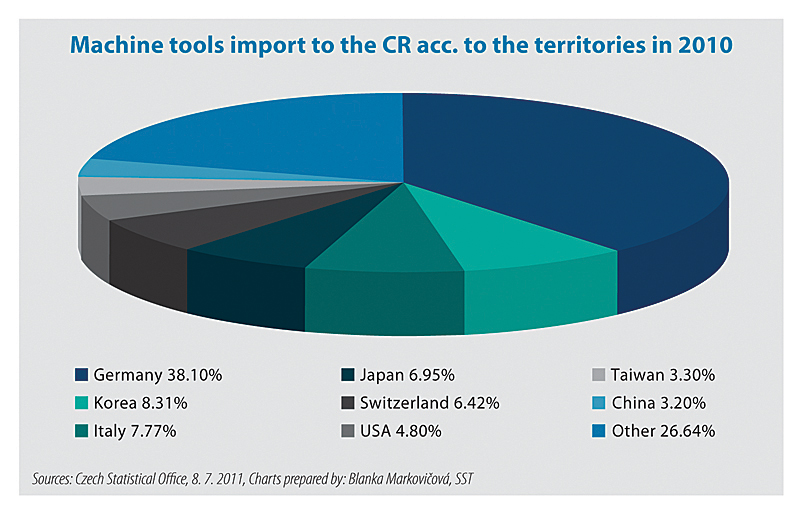

Commentary to Attached Charts

The attached charts (p. 5) make it clear that, in the long-term, Germany remains the most important partner of the Czech Republic in the field of metal-cutting and metal-forming machines, for both import and export. This fact is also evidenced by the considerable interest Czech companies have shown in participating in the most important trade fair event of this year, the EMO Hannover 2011. The Czech Republic is currently ranked third among European exporters of machines to Germany and fourth in the world-wide competition of exporters to the German market.

The top ten countries in the list of the CR’s foreign trade for 2010 include both countries that traditionally feature among the strongest in the field (USA, Italy, South Korea, Switzerland) and those that belong to dynamically developing regions within the world market area, i.e. to areas that call for operative exploitation of the currently high absorption potential (Russia, China, as well as Ukraine and Poland). In view of the current development on the world market, it is expected that Czech producers will attempt to enter the very important markets of Latin America and South Africa as soon as possible.

Supplemet of Czech Business and Trade 3/2011

Source: doingbusiness.cz

|